In a UT Dallas lab, chemistry graduate student Ashley Weiland dons protective gloves as she places materials into a high-temperature furnace, where the sample is destined to grow into a crystal.

If you want to bake the perfect cake, you might open the oven now and again to sneak a peek at its progress.

But if your aim is to make perfect crystals out of raw chemicals in a laboratory oven, temperatures in the range of 2,000 degrees Fahrenheit and a closed crucible present challenges to monitoring the process.

Ashley Weiland, a graduate student in the Department of Chemistry and Biochemistry at The University of Texas at Dallas, will have the opportunity to use X-rays to study such crystal growth as it unfolds — without having to open the oven.

The U.S. Department of Energy (DOE) recently selected Weiland for its Office of Science Graduate Student Research Program. One of 70 graduate students chosen nationwide — and the first one from UT Dallas in the program’s history — Weiland will receive funds to conduct part of her doctoral research on crystal growth at Argonne National Laboratory in Illinois in collaboration with a DOE scientist.

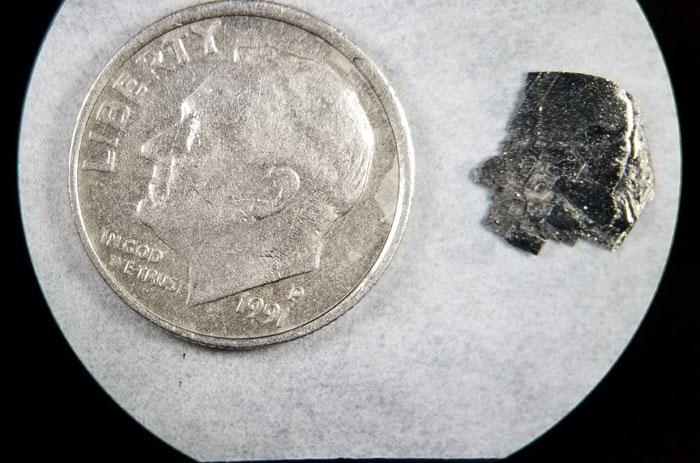

Weiland grew this crystal containing the elements cerium, cobalt and germanium in the lab of Dr. Julia Chan, professor of chemistry. At about 1 centimeter in size, the crystal is much larger than most intermetallic crystals grown in the lab.

Weiland, who received a bachelor’s degree in chemistry from Duquesne University, is pursuing her PhD as a member of Dr. Julia Chan’s solid-state chemistry laboratory at UT Dallas. Researchers in Chan’s group have developed methods for growing single crystals from individual elements from the periodic table as well as combinations of elements.

“As the elements are heated to high temperatures, their atoms rearrange in a periodic order to form a crystal,” said Chan, a professor of chemistry in the School of Natural Sciences and Mathematics. “The kind of compound you get and the properties of that material will be dictated by how those atoms are arranged, and it’s possible to discover something entirely new.”

Crystalline materials have a wide range of uses and are key components in computer technology, including cellphones, solid-state hard drives and batteries. Scientists conduct crystal-growth experiments to develop new materials and to study and measure their physical properties.

For example, Weiland and Chan recently collaborated with Dr. Bing Lv, assistant professor of physics at UT Dallas, on research examining the role of crystal-growth conditions on the magnetic properties of a specific type of crystal. That study was published online April 15 in the journal Inorganic Chemistry, with Weiland as the lead author.

“Growing crystals is difficult because when we put materials in the furnace, we don’t know when they start to crystallize, or when the properties we are looking for are actually emerging,” Weiland said. “We can’t check to see what’s happening or whether we’ve ‘overcooked’ the sample.”

“This is a game-changer for solid-state chemistry, and we’re very excited about using this technology. Usually, when we put materials into the furnace, it’s like a black box. With new data, we’ll now have an idea of reaction pathways, and we’ll know how best to grow crystals with desired electrical and magnetic properties.”

Dr. Julia Chan, professor of chemistry in the School of Natural Sciences and Mathematics

The Argonne lab is home to the Advanced Photon Source facility, which produces high-energy coherent X-rays for use in various research projects. As an X-ray beam scatters off an object, such as a tiny crystal, a diffraction pattern is produced. Scientists use these patterns to reconstruct a 3D image showing the exact arrangement of atoms and molecules in the crystal.

The experiments Weiland will perform at Argonne will generate many X-ray diffraction patterns over time — like a time-lapse movie — while the materials are in a high-temperature oven. With this data, she can monitor the formation of crystals from raw materials to finished products, taking measurements along the way to help develop just the right “recipe” for an impurity-free crystal with specific physical properties.

“This is a game-changer for solid-state chemistry, and we’re very excited about using this technology,” Chan said. “Usually, when we put materials into the furnace, it’s like a black box. With new data, we’ll now have an idea of reaction pathways, and we’ll know how best to grow crystals with desired electrical and magnetic properties.”

Dr. Juan E. González, dean of graduate education at UT Dallas, said Weiland and Chan exemplify the type of partnership the University has come to expect from its faculty mentors and their graduate students.

“Our graduate programs challenge students to think creatively and to immerse themselves in their education and training,” said Gonzalez, who holds the Francis S. Johnson Chair for Graduate Education. “The high caliber of faculty research at UT Dallas means that students like Ashley are well-prepared to compete for and be successful at opportunities such as the DOE Graduate Student Research Program.”