The Office Space of Stuart Yun BS’13

Stuart Yun BS’13

Stuart Yun BS’13

The Mojave Desert can overwhelm the senses. The sweltering afternoons and frigid nights make it impossible to dress for any occasion. The unforgiving brightness of a cloudless sky renders sunglasses ineffective. The howling winds kick up dust that coats wind-worn Joshua trees. Only the occasional sonic boom, high-altitude contrails and unidentified object in the sky indicate the history — and the future — of this desolate landscape. Nearly seven decades ago, Chuck Yeager broke the sound barrier in this Southern California desert, and it is here where many discoveries, first flights and world records have been set.

This is my office.

After graduating from UT Dallas with a bachelor’s degree in mechanical engineering, I moved to Southern California. I started my career at the Mojave Air and Space Port with Virgin Galactic/The Spaceship Company as its youngest engineer. I have since moved across the runway to Scaled Composites where I am currently an engineer for the Stratolaunch program.

This region is home to Edwards Air Force Base, Armstrong Flight Research Center, Lockheed Martin’s Skunk Works, the National Test Pilot School, NASA’s Jet Propulsion Lab and SpaceX. It is the hub of a renewed effort to explore beyond this planet.

There are certain creative milestones in human history that define a society: the ancient Egyptians had the Great Pyramid of Giza; the Ming Dynasty had the Great Wall of China; the Roman Empire had the Colosseum; and Western Europe had the Enlightenment and Scientific Revolution. Four thousand years from now, the petty issues of our time may be long forgotten, but I am confident that people will still gaze up at the stars, wondering about the society that dared to take the first steps on the moon and explore our solar system.

Those imaginings have also been mine. I have always sought to make an impact and potentially shape the course of our society through discovery. To be a part of this process is incredibly exciting.

Decades ago, space programs were funded by large governments with a focus on national defense. Then along came the X Prize Foundation’s space competition to spur the development of inexpensive spaceflights by the private sector. The first nongovernment organization to successfully carry manned spaceflights twice within two weeks would take the prize—an award of $10 million.

Behind this 21st-century version of a space race were three civilian innovators who also served on the X Prize Foundation’s board: Burt Rutan of Scaled Composites; Paul Allen of Microsoft Corp.; and Sir Richard Branson of Virgin Group. Rutan and Allen captured the X Prize in 2004 with an innovative space launch system. It included a carrier aircraft — White Knight — that lifted a passenger vehicle called SpaceShipOne and its rocket engine to high altitudes. SpaceShipOne would then be dropped, and its rocket would ignite, propelling the passengers into space.

From the momentum of that competition, the Mojave Air and Space Port, a civilian aerospace test center, has become the epicenter for experimental vehicles. This airfield is home to both Scaled Composites and Virgin Galactic, which are now developing SpaceShipTwo and White Knight Two for commercial spaceflight.

While at Virgin Galactic, I was tapped to be the subject matter expert for SpaceShipTwo’s mechanical flight control system. I developed and constructed the fixture and casting method for the aft end of the hybrid rocket motor for SpaceShipTwo’s propulsion system, conceived and implemented a flight-test data application for automated test results, and led the design and production for various systems in Mark 2 SpaceShipTwo — which is now named “Hope.”

My time at Virgin Galactic prepared me well for my next endeavor—a new venture with Scaled Composites. Founded by Rutan, Scaled Composites has pushed boundaries with its rapid prototype, one-off, experimental, milestone demonstration vehicles.

Rutan and the Scaled Composites crew have broken many world records, including the first nonstop, non-refueled flight around the world with Voyager, a bespoke aircraft designed by Scaled Composites. Many of Rutan’s designs are now hanging in various museums around the United States, including Voyager and SpaceShipOne at the Smithsonian Air and Space Museum in Washington, D.C.

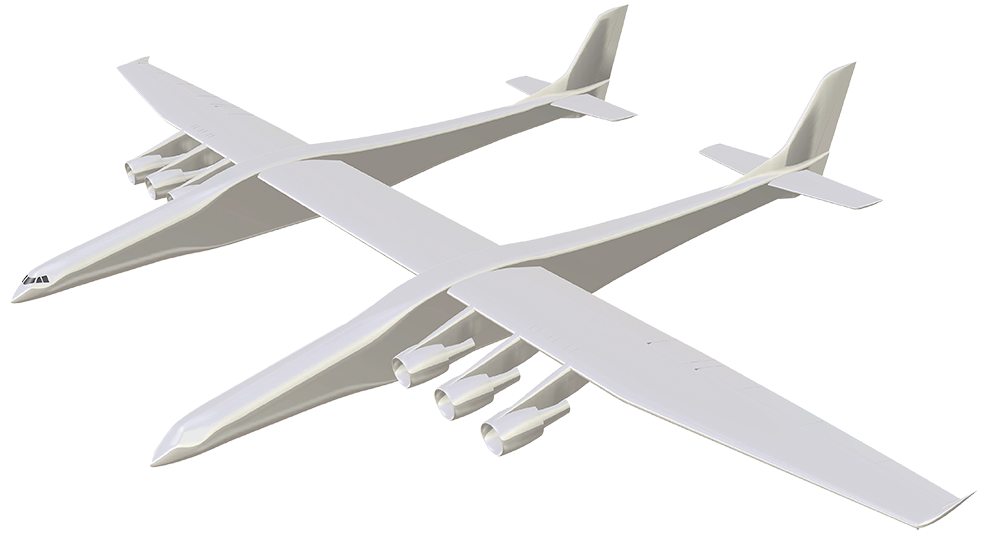

Scaled Composites is helping create the world’s largest aircraft, which will provide orbital, cost-effective access to space with greater safety.

Scaled Composites is helping create the world’s largest aircraft, which will provide orbital, cost-effective access to space with greater safety.

Scaled Composites is now developing an aerospace vehicle for Allen’s startup, Stratolaunch Systems. The mission is to provide a mobile system for a payload on a multistage rocket.

Stratolaunch plans to use an aircraft to propel payloads weighing thousands of pounds into low earth orbit with the capability to station where needed. The benefit of these flights includes the ability to launch a satellite into any orbit at any time from anywhere at a fraction of the cost of traditional programs. No longer will missions be tied to a handful of launchpads in the United States or delayed due to weather.

A mobile launch system of this magnitude requires a carrier aircraft on an enormous scale that has never been attempted. In fact, about 50 of my colleagues and I are creating the world’s largest aircraft. This carbon fiber composite aircraft will be wider than a football field (at more than 117 meters) and, with a gross weight of more than 1.3 million pounds, will require six Boeing 747 jet engines to provide enough thrust to lift this behemoth. What is even more impressive is that it is actually being constructed behind massive hangar doors at the Mojave Air and Space Port.

I am an engineer developing the flight control system for this lofty enterprise. Every day holds a new challenge in design work and a fast-paced schedule. This requires me to take a hands-on approach to engineering, and take the process from conception and design to fabrication and testing. Developing the system to pilot the world’s largest plane is no easy task, and can only be done with a great group of dedicated engineers and technicians. We take an interdisciplinary, hands-on approach to design in order to develop creative solutions.

At both Virgin Galactic and Scaled Composites, small and efficient teams are critical to the success of each project. All engineers must have hands-on experience to bring fresh perspectives to the table. Although grades are important in classes, hands-on skills and experience are equally valuable for your career. UT Dallas let me develop these skills through various opportunities in lab research, competitive teams and class projects. I can definitively say that the University has prepared me well for the roles I face in the cutting edge of aerospace.

Update from Stuart (08.30.2017): “I’m still at Scaled Composites working on the Stratolaunch program. Things have been moving at light speed here to get the world’s largest airplane flying and ready for rocket launches. I am now the engineer responsible for ground movements, steering, braking and some flight controls, and will be staffed in the control room. On May 31st, I was the engineer responsible for rolling out the aircraft out of the hangar in preparation for fuel testing.”

Stuart Yun BS’13 was a mechanical engineering student in the Erik Jonsson School of Engineering and Computer Science, where he conducted research in Dr. Matthew Goeckner’s laboratory. He also was a part of the Anson L. Clark Summer Research Program. Yun competed on the UTD robotics team that, under the mentorship of the late Dr. Cyrus Cantrell, won the 2011 BattleBots National Championship.